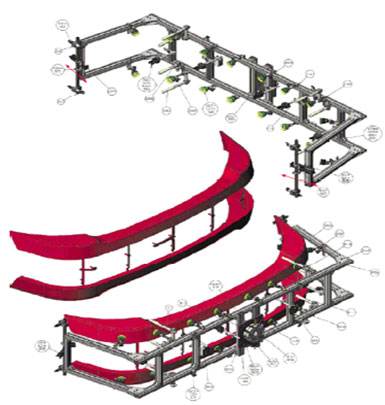

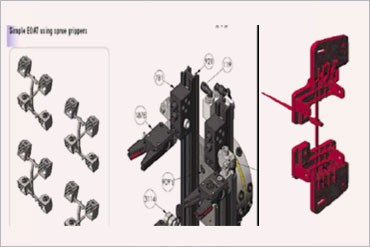

It is the hand (with all necessary tools) of the robot used to unload the injection moulding machine.

Job of a EOAT

- To take the moulded part out of the mould;

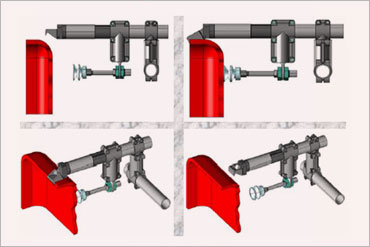

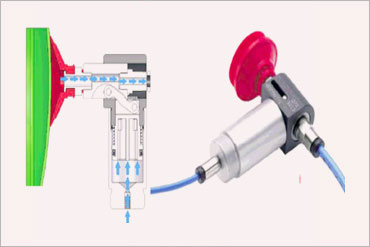

- To grip it firmly;

- To separate the moulded part from the sprue;

- To grip the sprue after cutting;

- To drop the sprue in the recycling machine;

- To unload the moulded part onto a pallet/belt.